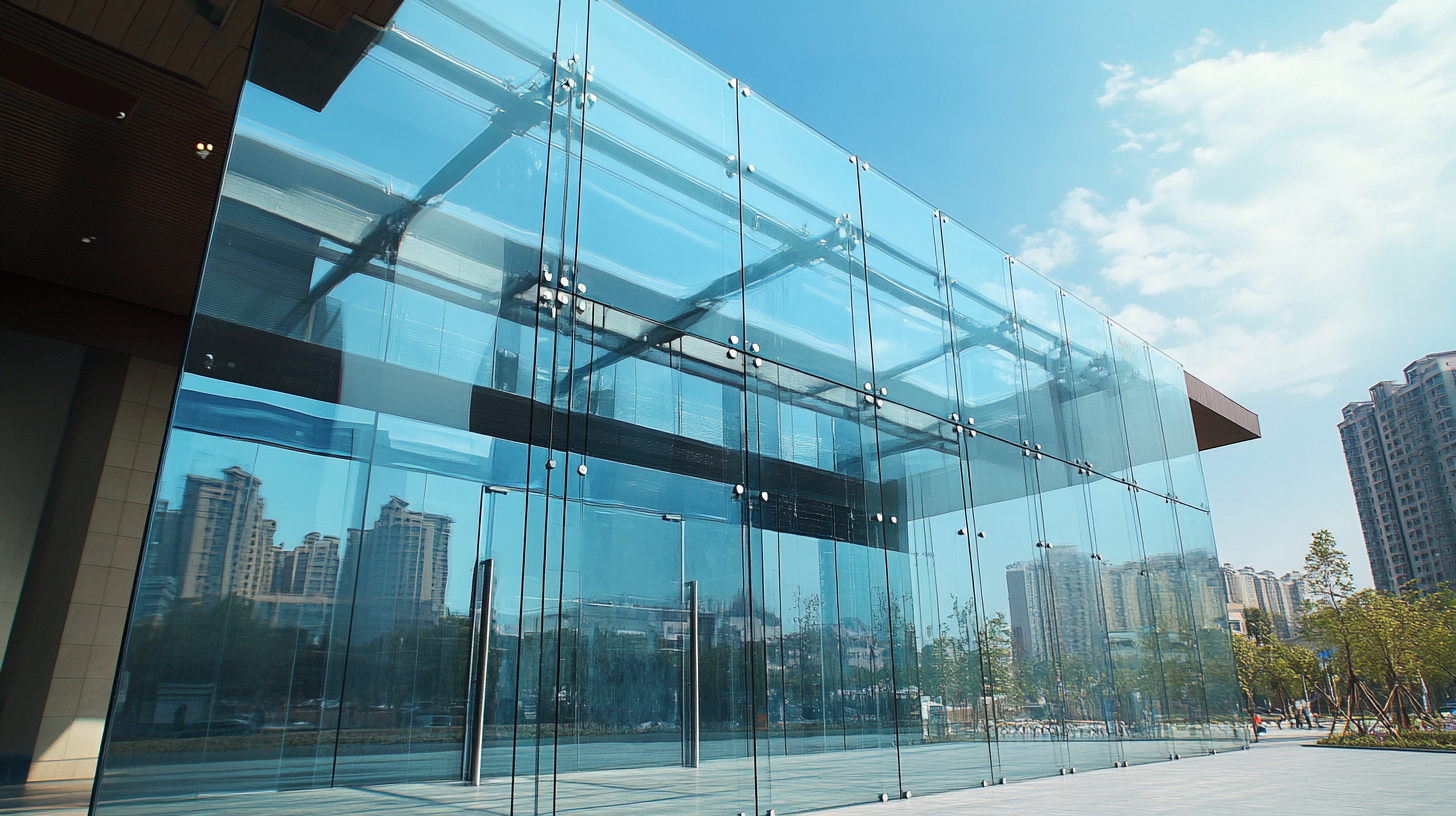

Crafted Excellence: China’s Premier Toughened Safety Glass for Global Safety Solutions

In an era where safety and durability are paramount, "Toughened Safety Glass" stands out as a beacon of innovation and reliability. As global industries increasingly prioritize protective solutions, China has emerged as a leader in crafting high-quality toughened safety glass that meets rigorous international standards. This blog will delve into the key reasons why this advanced material has become essential for various applications, from architectural designs to automotive uses. We will explore the unique properties of toughened safety glass, such as its ability to withstand impact and thermal stress, along with the innovative manufacturing processes that enhance its performance. By understanding the significance of toughened safety glass and its contributions to global safety solutions, we can appreciate its pivotal role in protecting lives and property around the world. Join us as we uncover the excellence behind China's premier toughened safety glass and its impact on our safety landscape.

Challenges in Achieving Consistent Toughened Glass Quality

Achieving consistent quality in toughened safety glass poses numerous challenges for manufacturers, despite the growing demand for such materials in various industries. According to a report by Market Research Future, the global market for safety glass is expected to exceed $75 billion by 2025, with a considerable portion of that attributed to advancements in construction and automotive sectors. However, the production process involves complex thermal treatments that, if not carefully controlled, can lead to inconsistencies in strength and durability.

Variations in raw materials, differences in annealing times, and temperature fluctuations in furnaces can all contribute to the quality discrepancies observed in toughened glass products. A study published in the Journal of Glass Science and Technology found that up to 30% of production batches may show weaknesses if parameters are not stringently monitored. This highlights the need for stringent quality control measures and continual investments in technology to enhance production reliability. Ensuring uniform quality not only boosts product safety but also secures the manufacturer's reputation in a competitive global market.

Identifying Common Defects in Toughened Safety Glass Products

When it comes to toughened safety glass, maintaining high standards is critical to ensuring both functionality and safety. However, manufacturers and suppliers often encounter common defects that can compromise the integrity of these products. One of the most prevalent issues is surface imperfections, such as scratches or pits, which can weaken the glass and detract from its aesthetic appeal. It's essential for manufacturers to implement stringent quality control measures to detect these imperfections during the production process.

Another significant defect to watch for is inconsistent thickness. Variability in thickness can lead to uneven stress distribution when the glass is subjected to impact or thermal changes, increasing the risk of breakage. Ensuring uniform thickness is vital, not only for safety but also for the reliability of the glass in various applications. Regular testing and adherence to industry standards can help identify and rectify these inconsistencies before the glass reaches the market, safeguarding consumers and enhancing the overall quality of toughened safety glass products.

The Impact of Manufacturing Processes on Glass Safety Standards

The manufacturing processes of toughened safety glass play a crucial role in setting and maintaining the stringent safety standards required in today's market. According to a report by the International Glass Association, approximately 60% of glass-related injuries can be attributed to the use of substandard materials. This underscores the necessity for manufacturers to adhere to rigorous production techniques that enhance impact resistance and thermal stability. By utilizing advanced tempering processes, manufacturers in China have positioned themselves as leaders in the market, ensuring that their products not only meet but exceed global safety standards.

The precise control over heat treatment during the manufacturing process significantly affects the mechanical properties of toughened glass. A study published in the Journal of Materials Science reveals that properly tempered glass can withstand temperatures of up to 300°C and impacts of 1000 Newtons without breaking. This durability is essential, especially in high-stakes environments such as skyscrapers and transportation systems, where safety cannot be compromised. As the demand for robust safety solutions escalates globally, China's dedication to enhancing manufacturing processes highlights its commitment to providing high-quality glass that meets the evolving needs of various industries.

Addressing Supply Chain Issues in Toughened Glass Production

The challenges faced by supply chains globally have become increasingly evident, particularly in the production of toughened safety glass. Scarcity of raw materials and disruptions linked to geopolitical factors have necessitated a reevaluation of procurement and logistics strategies. A recent industry report indicates that about 68% of companies have shifted their supply chain strategies to prioritize resilience, highlighting the intricate balance between efficiency and robustness. This shift aims to ensure that businesses can adapt to unforeseen disruptions while maintaining product quality.

In the toughened glass sector, implementing advanced technologies such as Industry 4.0 can significantly enhance production efficiency and sustainability. Reports show that integrating smart manufacturing processes could reduce operational costs by up to 15%, while also minimizing waste through better resource management. Furthermore, innovative recycling solutions, such as converting glass waste into high-value materials, can pave the way for a circular economy, allowing for sustainable practices within the industry. As the demand for safe and reliable glass solutions escalates in various global markets, addressing these supply chain vulnerabilities will be essential for fostering long-term business growth and sustainability in the toughened glass sector.

Crafted Excellence: China’s Premier Toughened Safety Glass for Global Safety Solutions - Addressing Supply Chain Issues in Toughened Glass Production

| Dimensions (mm) | Thickness (mm) | Application Area | Supply Chain Status | Market Demand (Units per Month) |

|---|---|---|---|---|

| 1200 x 1000 | 4 | Commercial Buildings | Stable | 15,000 |

| 1500 x 1200 | 6 | Residential Windows | Moderate Disruptions | 10,000 |

| 1000 x 800 | 5 | Automotive Glass | Unstable | 8,000 |

| 600 x 600 | 3 | Shower Doors | Stable | 12,000 |

Market Trends Affecting the Demand for Toughened Safety Glass Solutions

The demand for toughened safety glass solutions is witnessing significant growth, driven by evolving market trends and technological advancements. A recent industry report indicates that the automotive glass market is anticipated to reach a valuation exceeding USD 50.65 billion by 2032, with a remarkable compound annual growth rate (CAGR) of over 5.1% from 2025 to 2032. This growth underscores a heightened awareness of safety regulations in the automotive sector, where toughened glass plays a critical role in enhancing vehicle safety and durability.

Tip: When considering toughened safety glass for your projects, always prioritize sourcing from reputable manufacturers to ensure compliance with international safety standards.

Tip: Stay informed about regulatory changes in the automotive and construction industries, as these can directly impact your material choices and project timelines.